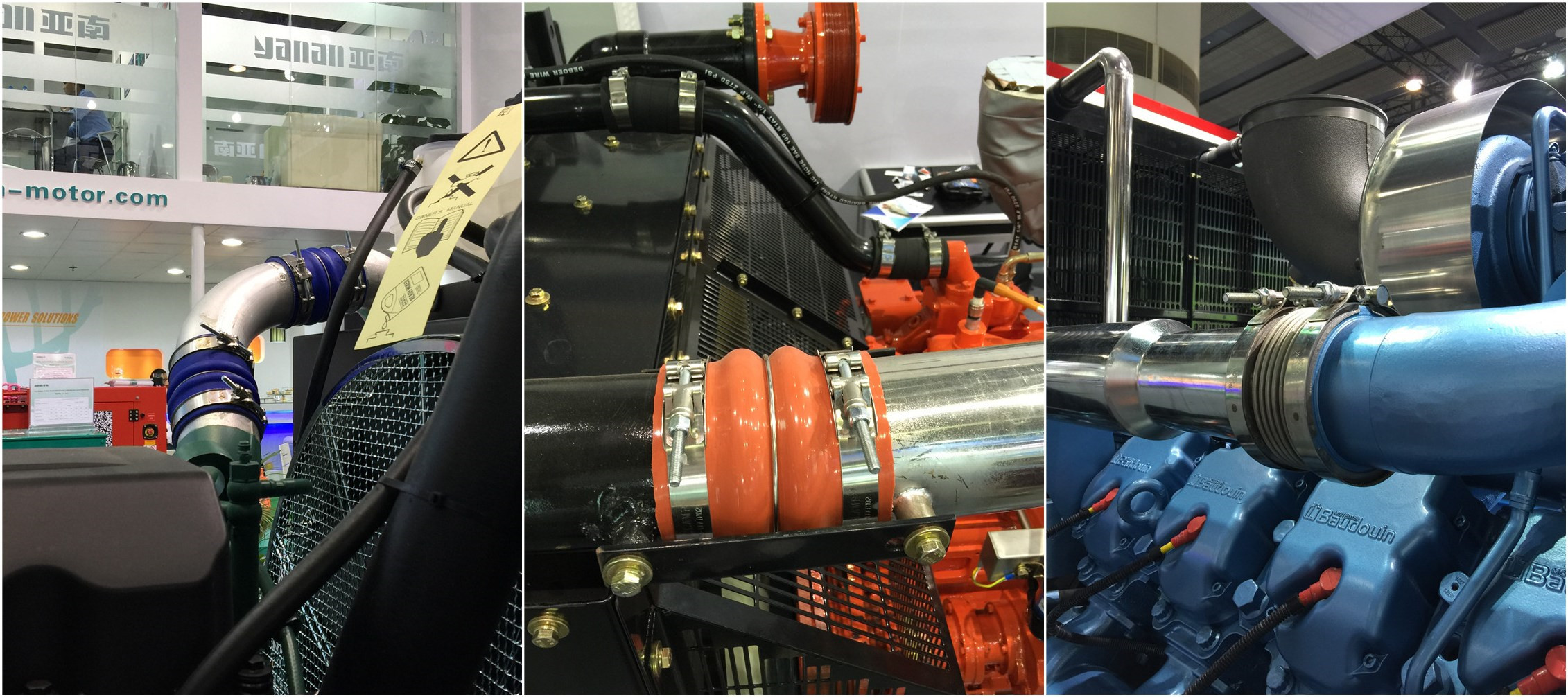

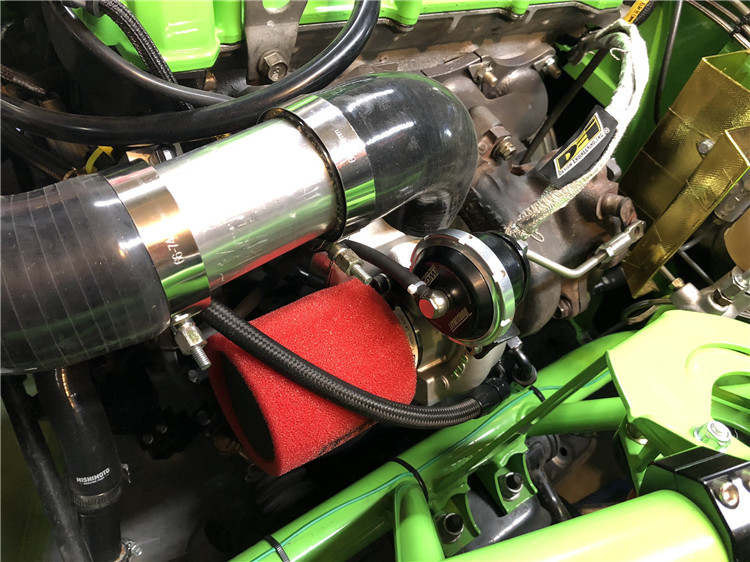

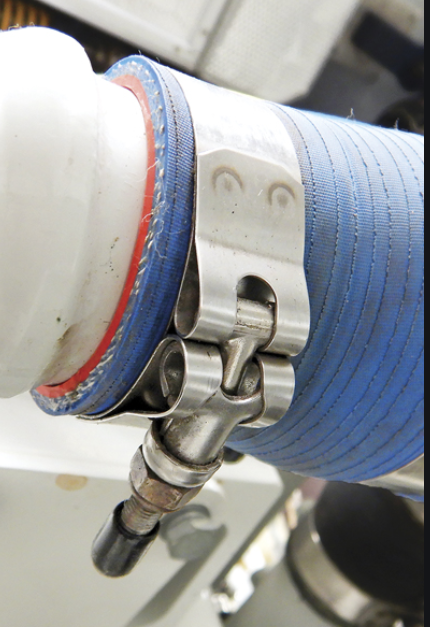

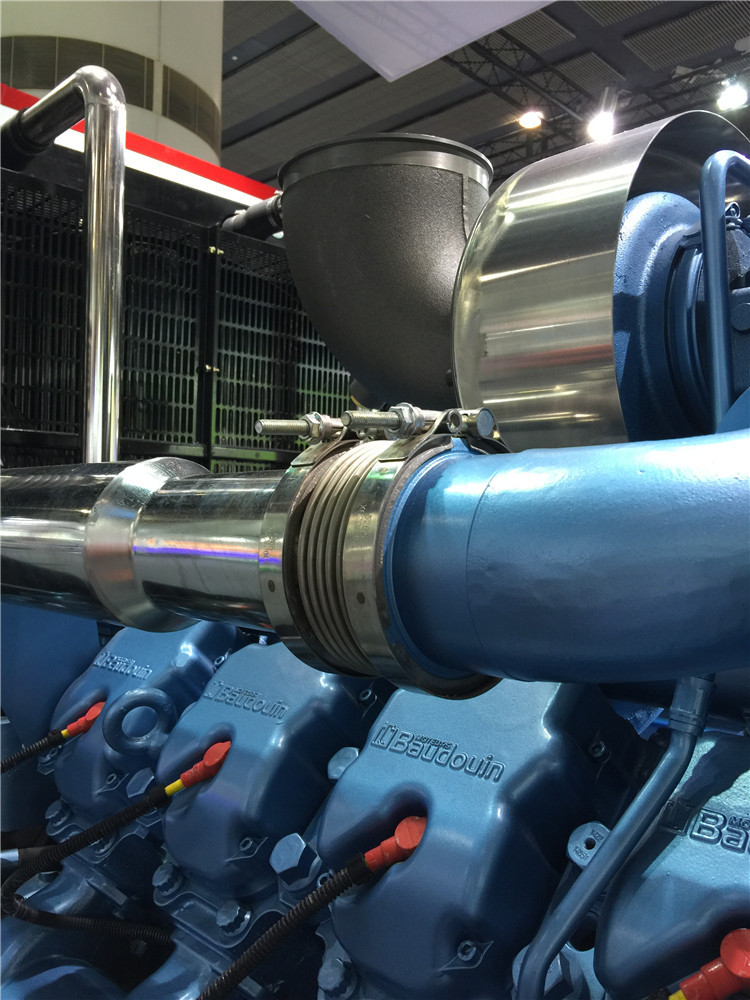

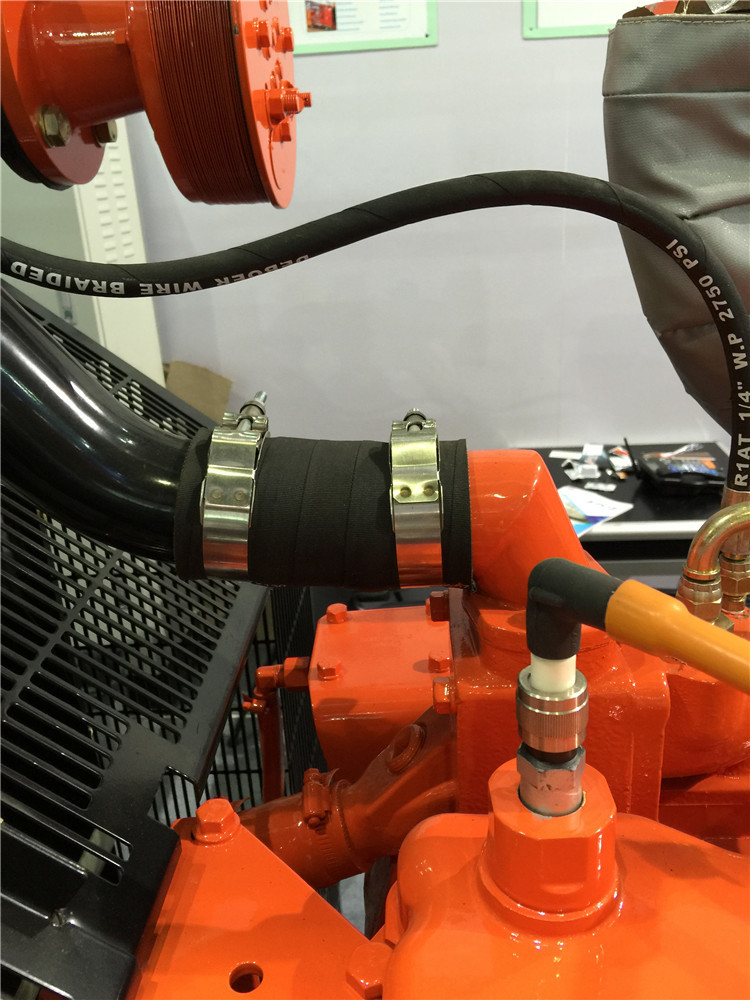

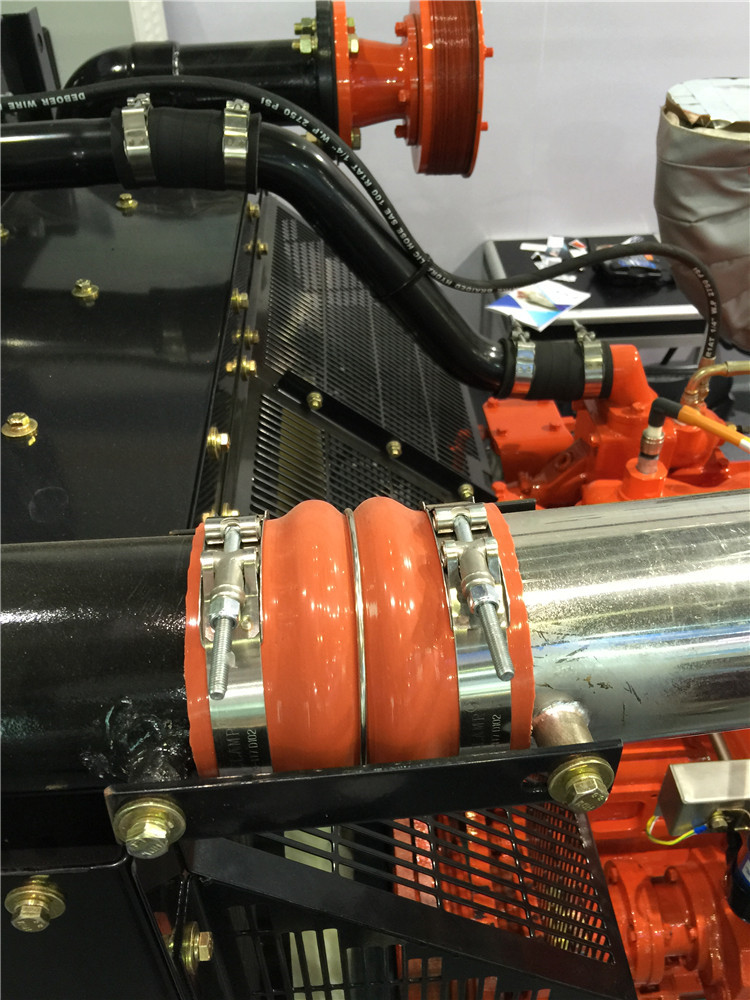

I-Flexible Bolt Clamp Stainless Steel Band Constant Tension Silicone Radiator Hose Clamp isetshenziswa kakhulu ezimotweni ezikhethekile, emikhunjini, imishini yemishini, imishini yamakhemikhali, amapayipi okumunca uwoyela namanzi, amapayipi ancibilikisa i-acid-base, amapayipi okufafaza, amapayipi aqiniswe ngocingo lwensimbi kanye namanye amalunga epayipi ukuze kuqiniswe ukuqina. Umklamo wesiphethu esijikelezayo unikeza isinxephezelo somthwalo ozithwalayo (ukucindezela okuqhubekayo) futhi ubonakala ngokuvimbela ukuvuza ngenxa yokushintshashintsha kwezinga lokushisa. Izicelo ezijwayelekile zifaka phakathi izinhlelo zokungenisa umoya ezithwala iloli ezisindayo kanye nokupholisa.

Izinga lokushisa eliphezulu lenkonzo ye-locknut lingu-250° (F).

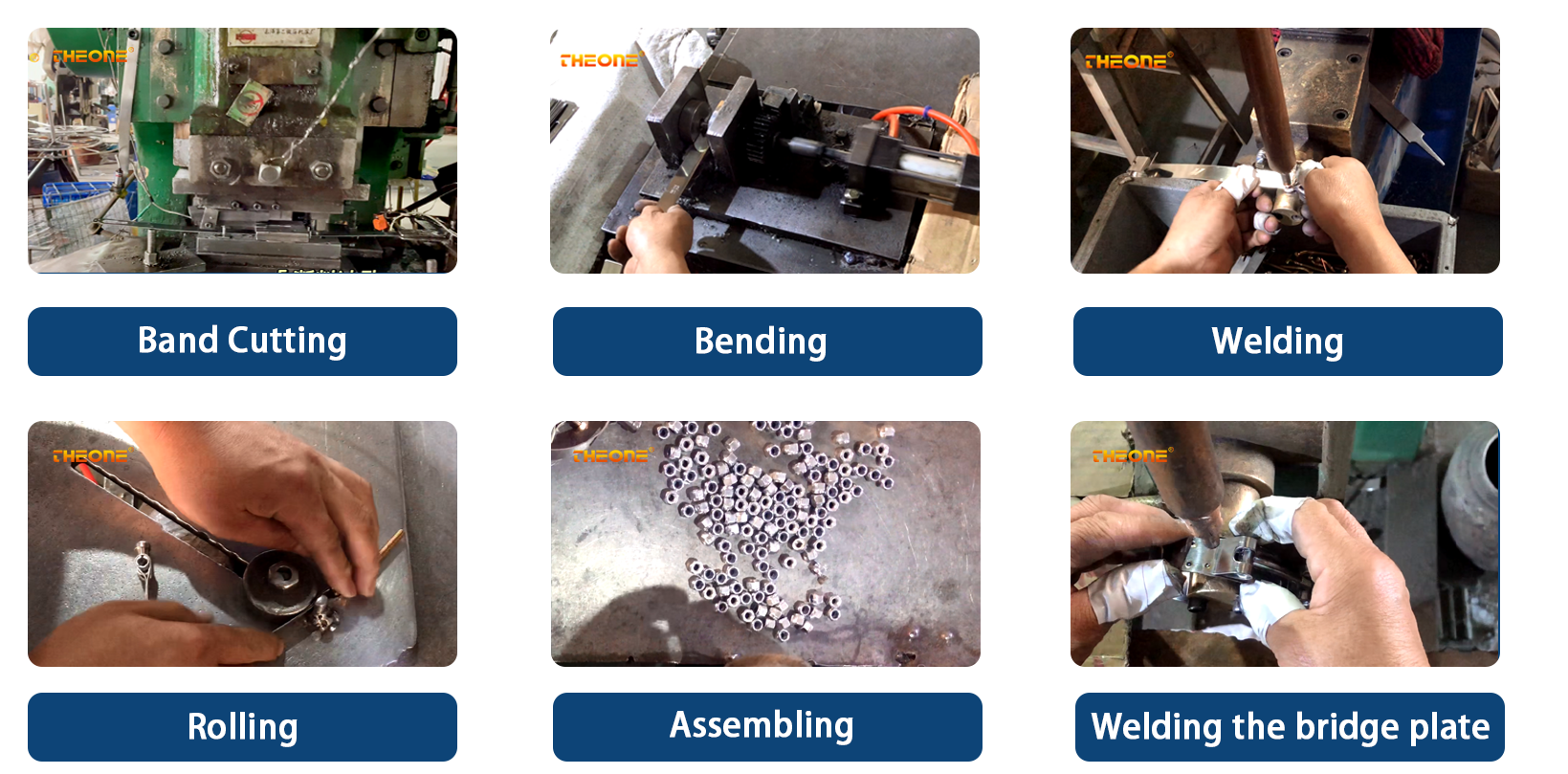

Ama-clamp e-T-bolt akhiqizwa ngezinto zokwakha ngokuhambisana nezindinganiso zomkhakha ukuze anikeze ikhwalithi ephezulu kanye nokusebenza okulinganayo.

I-Zinc Plating yenziwa ngokwezidingo zemboni, futhi amazinga ethu ensimbi engagqwali enziwe ngokwe-AISI kanye nezinye izindinganiso ezibalulekile zomhlaba wonke.

Ungaqiniseka ukuthi uthola izinga lezinto eziceliwe njalo uma u-oda kithi.

-

CHA.

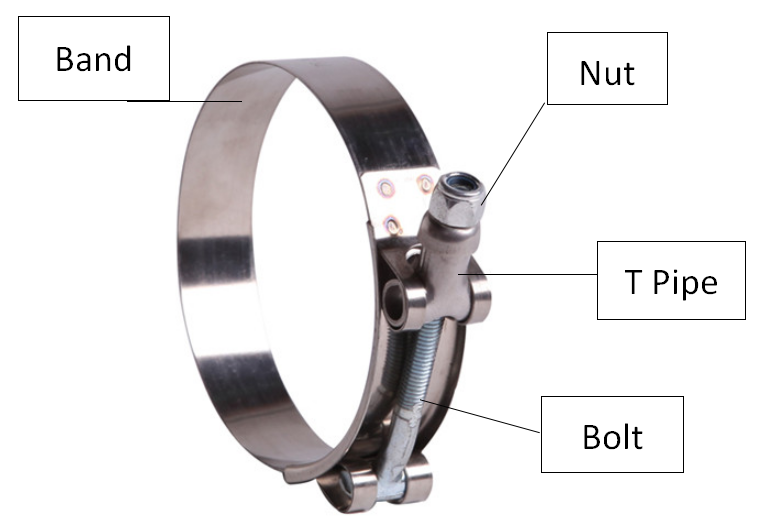

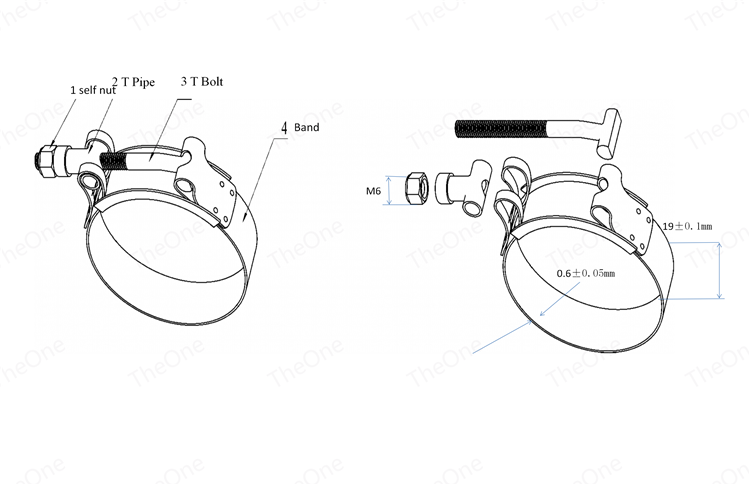

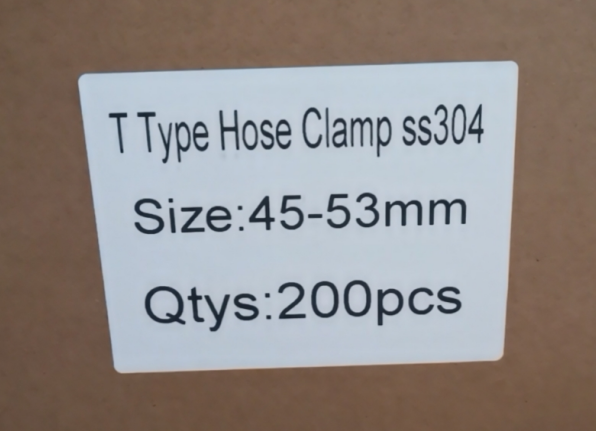

Amapharamitha Imininingwane 1.

Ububanzi bomkhawulokudonsa*ukujiya 19mm*0.6mm 2.

Usayizi 35-40mm kubo bonke 3.

Isikulufu I-M6*75mm 4.

Ilayisha i-Torque 20I-Nm 5

I-OEM/ODM I-OEM/ODM yamukelekile 6

Ubuso Ukupholisha/Okuphuzi okumbozwe nge-zinc/Okumhlophe okumbozwe nge-zinc 7

Mi-aterial Insimbi engagqwali: uchungechunge lwama-200 kanye nochungechunge lwama-300/insimbi egayiwe

I-Flexible Bolt Clamp Stainless Steel Band Constant Tension Silicone Radiator Hose Clamp yakhelwe ukuhlinzeka ngokuxhumana ngaphandle kokuvuza. Imiphetho ye-band iyindilinga ukuvikela ipayipi.

Izinga lokushisa eliphezulu lenkonzo ye-locknut lingu-250° (F).

I-Flexible Bolt Clamp Stainless Steel Band Constant Tension Silicone Radiator Hose Clamp yenziwa ngezinto ezihambisana namazinga omkhakha ukuze inikeze ikhwalithi ephezulu kanye nokusebenza okulinganayo.

I-Zinc Plating yenziwa ngokwezidingo zemboni, futhi amazinga ethu ensimbi engagqwali enziwe ngokwe-AISI kanye nezinye izindinganiso ezibalulekile zomhlaba wonke.

Ungaqiniseka ukuthi uthola izinga lezinto eziceliwe njalo uma u-oda kithi.

I-torque yokufaka enconywayo ingu-13Nm.

Kuyi-clamp enamandla aphezulu, ethembekile enezinhlelo zokusebenza eziningi kokubili emakethe yezentengiselwano neyezimboni okuhlanganisa ukuxhumana kwamapayipi kanye namapayipi omoya, uwoyela, amanzi, ezinye izinhlobo zemigqa yoketshezi ephansi, ukungena komoya enjinini, ukukhishwa komoya, ipayipi kanye nezihlungi

I-TheOne inikeza izingxenye ezisezingeni eliphezulu ezimbonini eziningi ezahlukene. Ama-T-bolt clamp ethu ayasebenza futhi atholakala ngezinhlobo eziningana.

Imikhiqizo yethu ivame ukusetshenziswa ezimbonini kanye nezinhlelo zokusebenza ezifana nalezi:

- Izicelo Zasolwandle

- Ezolimo

- Izimoto

- Amaloli Anzima

- Izicelo Zezimboni

- Izinhlelo Zokunisela

| Uhla Lwezibambo | Ububanzi bomkhawulo | Ubukhulu | KUYA ku-Ingxenye No. | |||

| Ubuncane(mm) | Ubuningi(mm) | (mm) | (mm) | W2 | W4 | W5 |

| 35 | 40 | 19 | 0.6 | I-TOTS40 | I-TOTSS40 | I-TOTSSV40 |

| 38 | 43 | 19 | 0.6 | I-TOTS43 | I-TOTSS43 | I-TOTSSV43 |

| 41 | 46 | 19 | 0.6 | I-TOTS46 | I-TOTSS46 | I-TOTSSV46 |

| 44 | 51 | 19 | 0.6 | I-TOTS51 | I-TOTSS51 | I-TOTSSV51 |

| 51 | 59 | 19 | 0.6 | I-TOTS59 | I-TOTSS59 | I-TOTSSV59 |

| 54 | 62 | 19 | 0.6 | I-TOTS62 | I-TOTSS62 | I-TOSSSV62 |

| 57 | 65 | 19 | 0.6 | I-TOTS65 | I-TOTSS65 | I-TOTSSV65 |

| 60 | 68 | 19 | 0.6 | I-TOTS68 | I-TOTSS68 | I-TOTSSV68 |

| 63 | 71 | 19 | 0.6 | I-TOTS71 | I-TOTSS71 | I-TOTSSV71 |

| 67 | 75 | 19 | 0.6 | I-TOTS75 | I-TOTSS75 | I-TOTSSV75 |

| 70 | 78 | 19 | 0.6 | I-TOTS78 | I-TOTSS78 | I-TOTSSV78 |

| 73 | 81 | 19 | 0.6 | I-TOTS81 | I-TOTSS81 | I-TOTSSV81 |

| 76 | 84 | 19 | 0.6 | I-TOTS84 | I-TOTSS84 | I-TOTSSV84 |

| 79 | 87 | 19 | 0.6 | I-TOTS87 | I-TOTSS87 | I-TOTSSV87 |

| 83 | 91 | 19 | 0.6 | I-TOTS91 | I-TOTSS91 | I-TOTSSV91 |

| 86 | 94 | 19 | 0.6 | I-TOTS94 | I-TOTSS94 | I-TOTSSV94 |

| 89 | 97 | 19 | 0.6 | I-TOTS97 | I-TOTSS97 | I-TOTSSV97 |

| 92 | 100 | 19 | 0.6 | I-TOTS100 | I-TOTSS100 | I-TOTSSV100 |

| 95 | 103 | 19 | 0.6 | I-TOTS103 | I-TOTSS103 | I-TOTSSV103 |

| 102 | 110 | 19 | 0.6 | I-TOTS110 | I-TOTSS110 | I-TOTSSV110 |

| 108 | 116 | 19 | 0.6 | I-TOTS116 | I-TOTSS116 | I-TOTSSV116 |

| 114 | 122 | 19 | 0.6 | I-TOTS122 | I-TOTSS122 | I-TOTSSV122 |

| 121 | 129 | 19 | 0.6 | I-TOTS129 | I-TOTSS129 | I-TOTSSV129 |

| 127 | 135 | 19 | 0.6 | I-TOTS135 | I-TOTSS135 | I-TOTSSV135 |

| 133 | 141 | 19 | 0.6 | I-TOTS141 | I-TOTSS141 | I-TOTSSV141 |

| 140 | 148 | 19 | 0.6 | I-TOTS148 | I-TOTSS148 | I-TOTSSV148 |

| 146 | 154 | 19 | 0.6 | I-TOTS154 | I-TOTSS154 | I-TOTSSV154 |

| 152 | 160 | 19 | 0.6 | I-TOTS160 | I-TOTSS160 | I-TOTSSV160 |

| 159 | 167 | 19 | 0.6 | I-TOTS167 | I-TOTSS167 | I-TOTSSV167 |

| 165 | 173 | 19 | 0.6 | I-TOTS173 | I-TOTSS173 | I-TOSSSV173 |

| 172 | 180 | 19 | 0.6 | I-TOTS180 | I-TOTSS180 | I-TOSSSV180 |

| 178 | 186 | 19 | 0.6 | I-TOTS186 | I-TOTSS186 | I-TOTSSV186 |

| 184 | 192 | 19 | 0.6 | I-TOTS192 | I-TOTSS192 | I-TOTSSV192 |

| 190 | 198 | 19 | 0.6 | I-TOTS198 | I-TOTSS198 | I-TOTSSV198 |